The Role of Inventory Management Software in Construction

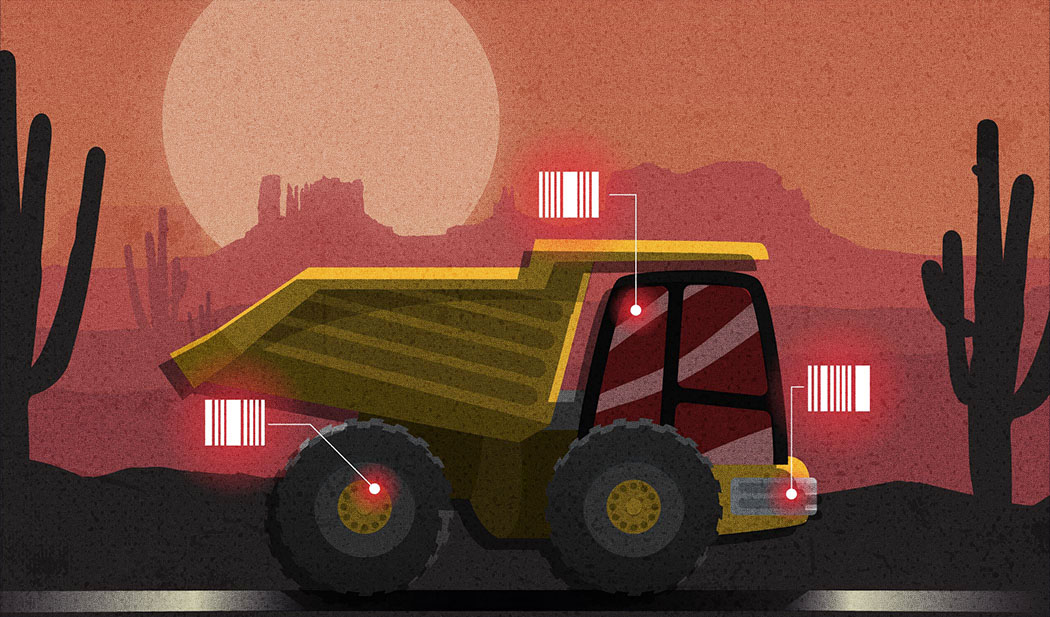

Take a moment to imagine a piece of construction equipment.

It’s strong, right? Towering, steadfast, powerful. This monstrous beauty literally navigates the trenches to help us build a better world.

But beyond that hard, canary-yellow exterior, that construction equipment has a soft and delicate interior. It needs—nay, deserves!—the same love and care as any other heavy-duty truck.

To get these wonderful machines the maintenance and repairs they need in a timely manner, there needs to be a better way. Enter the role of construction inventory management.

Challenges in Construction Inventory Management

First off, let’s take a look at some common challenges fleets and repair shops face when it comes to inventory management.

- Overstocking: Holding excess inventory can tie up capital that could otherwise be used more productively elsewhere in the shop. It also increases storage costs and risks of aging.

- Decreased Productivity: Spending more time checking for inventory and waiting for supplies rather than focusing on primary tasks can significantly reduce overall productivity around the shop.

- Understocking: A lack of necessary materials or tools can halt construction activities, leading to project delays and increased costs due to last-minute purchasing.

- Theft, Loss, and Damage: Without proper tracking systems, materials and tools are vulnerable to unfortunate damage or disappearances. This not only leads to direct financial losses but also disrupts project schedules as replacements are sourced and delivered.

- Financial Misreporting: Misreported inventory levels can distort the balance sheet, affect profit and loss statements, and result in poor decision-making—further complicating project management and financial planning.

Any of these sound familiar? Fortunately, inventory management can help mitigate these issues and streamline operations.

Key Benefits of Implementing Inventory Management Software in The Construction Industry

Now, you may be thinking, okay—you understand my struggles, but why software? That’s just another whole time-consuming process to learn. Or a time-consuming process to teach to all the shop’s techs, which means time-consuming training sessions, too.

We’re glad you asked. Hear us out to learn the key benefits below:

Enhanced Tracking and Visibility

Real-time monitoring means no more guessing games about where your parts and materials are or when they’ll show up. This keeps repairs quick and efficient and saves you from those all-too-common “Where did we put that?” moments.

Cost Savings and Waste Reduction

We’ve said it before and we’ll say it again: your inventory isn’t your savings account.

Your inventory is definitely an asset, but it should be a well-maintained one. Parts should be moving, not accumulating dust—or accumulating in general. If you aren’t handling your inventory properly, you may even be losing money on it.

Construction inventory management software helps you better track what’s moving in and out so you don’t end up buying more than you need.

Improved Procurement and Supply Chain Efficiency

Smooth ordering processes? Say no more! Improved inventory management means you’re always one step ahead. By setting minimum thresholds for each part, you’ll never be caught empty-shelved again since the software will automatically send alerts when it’s time to reorder.

Accountability and Security

With an organized system for inventory control, it’s a lot easier to keep track of everything. Less loss, less fuss, and a whole lot fewer items mysteriously disappearing via wormholes or rips in the space-time continuum.

Features to Look for in Construction Inventory Management Software

Before you invest in any old software, there are some key features to consider. This should give you a solid idea of what to look for in the software options out there—and maybe also convince you that Fullbay is exactly what you need.

Barcode and RFID Scanning

Ever wish you had a magic wand to instantly know where everything is? Well, barcode and RFID scanning is pretty much that. This feature allows you to wave a scanner over items and voilà! You know exactly what’s in stock and where it’s located.

Integration with Project Management Tools

What other tools or software do you use on a daily basis? Inventory management software that integrates with service orders, estimates, and so on ensures that everything is working in tandem. Plus it sets you up for task automation and info synchronization so there’s less mundane work for you and your team.

Customizable Reporting

Customizable reporting adapts to your specific needs, allowing you to focus on what matters most for project analysis, budgeting, and forecasting. With the right information at your fingertips, you can make better purchase decisions, spot operational bottlenecks, and find new opportunities to boost revenue.

Mobile Accessibility

Mobile accessibility allows on-site managers and workers access to important inventory data directly from their mobile devices—a far cry from the days when everyone relied on binders full of spreadsheets or made frequent trips back to the workstation just to check on stock levels.

Give Your Construction Equipment the Love They Deserve

So again, we ask you to think about the construction equipment in your life. The building you’re sitting in, the roads you drive on—none of it would be possible without hard-working bulldozers, graders, trenchers, excavators, and so many more.

Showing your appreciation doesn’t have to be a grand, bold statement. It’s all about the little things, like not making that poor vehicle wait for days to get the part it needs.

With Fullbay, we’re all about saving time for you–and getting heavy-duty trucks of all shapes and sizes the care they need to stay in peak form. Whether it’s quick estimates and invoicing, balanced inventory levels, or tech-friendly service order workflows, we would love to show you what you’ve been missing. Request a free demo to learn more!