What Are Comeback Repairs?

Who doesn’t like a great comeback?

Rocky vs. Drago.

Cubs vs. Indians (unless you’re from Cleveland).

A great response to an insult.

But what about a comeback in your shop? Yikes.

We can do without that kind of comeback.

Unfortunately, just about every shop faces comeback repairs at some point. What exactly are they, how can you stop them, and who should be held responsible? Qualified diesel mechanics are often highly-paid individuals. But when you have to deploy them gratis on a warranty job, you start losing money fast.

What Are Comeback Repairs?

If you’ve ever sent a truck on its way, only to see it again for the same problem, then you’ve dealt with the pain of comeback repairs.

Let’s say a customer arrives with a stuttering transmission. Your techs diagnose a problem and get to work. The problem is solved – or it seems to be. Much to everyone’s surprise, the customer is back very soon with that same stuttering transmission.

They’re not happy. You’re not happy. Not only are you on the hook for finding out what went wrong with that repair (and making it right), you’re also facing an erosion in the trust your customer puts in you and your shop.

The Cost of a Comeback

As bad as comebacks are, even worse is not knowing how they are hurting you.

Just what kind of time and financial impact they’ll have on your shop will depend on what kind of comebacks you receive, so here’s a quick overall look at the immediate costs you’ll incur, both time and finance-wise:

- A customer arrives with a comeback repair

- You or one of your techs need to inspect the vehicle to confirm the problem

- Confirm the issue or diagnose a separate one

- Is it a failed part, or is the technician at fault?

- Determine how to proceed – will you re-repair?

- Will the same tech work on it?

- Will a different tech, or your service manager, or you take over?

- Will you complete the repair for free, charge a lesser rate, or come to another agreement?

Look at the above list and work out how many hours you and your staff will be putting toward this comeback repair.

Time is money.

How to Reduce Comeback Repairs

Now that you have some idea of how a comeback repair can impact your business, let’s discuss a few ways to reduce their occurrence.

1. Hold the Technicians Accountable

You need to hold the original technician accountable when comeback repairs come in. Whether they do the comeback, or another technician does it, you should deduct the hours spent on the comeback repair from the original technician’s efficiency numbers.

It makes the most sense to do this deduction in the week of the comeback repair, not the original repair. This way your numbers for the week aren’t inflated, and the tech being held accountable has time to scramble and potentially make up the difference.

This incentivizes them to get the repair right the first time.

You should also track the service order of the original repair, cause of the comeback, and a recommendation on how to avoid comebacks like this in the future.

2. Verify Repairs

In an ideal world, your techs would perform a repair quickly and correctly the first time. The reality, of course, is that sometimes mistakes happen. You can add another layer between your shop and potential comebacks by providing a secondary inspection – have another tech or a manager quickly look over a repair when it’s completed.

Repair verification does hinge on your shop having both the manpower and financial ability to spare someone to conduct these checks. It’s not a regular occurrence in most heavy-duty repair shops, but if you’re facing a lot of comebacks, you should consider implementing this step until you sort out why these comebacks keep happening.

3. Track Your Repairs

Tracking your comeback repairs lets you see exactly what kinds of repairs are triggering problems, and allows you to investigate them. For example, are you having a lot of comebacks on turbos? What kind of turbos are you installing or repairing? Should you switch manufacturers? Or do your techs need additional education when it comes to working on turbos?

You may be able to zero in on a particular tech who isn’t doing well, or even a particular kind of repair that you may opt to stop performing.

Billing Comeback Repairs

Here’s the thousand-dollar question: do you charge for a comeback repair?

The answer is maybe.

If it’s a failed part, it may be covered under a manufacturer’s warranty. You will need to decide how you want to handle labor to install a new one.

If it’s due to your tech, there are several ways you can handle it. The repair may come out of their salary. If your comebacks are largely tied to one tech, you may have some staffing decisions to make.

But how do you handle the billing for a comeback?

Use Credit Memos

Many shops are tempted to just zero out the invoices for heavy-duty comeback repairs. Don’t fall into this trap. When you zero out the invoice, you wipe away the whole financial record of what just happened. You’re essentially erasing everything that was done, making it impossible to run a report that shows how much you spent on comebacks or warranty work last week.

Instead of zeroing out the invoice, create a credit memo and use that to pay the invoice. Using a credit memo has many advantages. It works just like a payment, so the customer sees they don’t owe for the repair. It is a record of what happened, so you can always go back and jog your memory. And it is highly customizable: you get to choose where the expense hits (this allows you to track all your heavy-duty comeback repairs in one account).

For example, say you did an $800 comeback repair. You create the invoice, but then zero it out. It’s not a real job, so there is no labor or parts revenue, right? Wrong. Any time work is done in the shop, you need a record of it in your revenue. You should not be zeroing out invoices.

Instead, you take the $800 invoice, and create a credit memo for the same amount. You have the chance to pick something like “warranty expense” as the offset account. Then you apply this credit memo to the invoice, just like you would apply a payment. The invoice is cleared out, the revenue is recognized, but then the entire revenue is offset by this $800 warranty expense.

If you do it this way, each time a comeback happens, the cost to the shop drops into the warranty expense account. You can then easily report how much you’re spending on heavy-duty comeback repairs.

Don’t Bill at a Lower Rate!

If you’re recognizing the revenue on a comeback repair, should you do it at a lower rate? No. It is important that you recognize the full revenue, so that when you wipe it away with your warranty expense, you see exactly what the comeback cost you as both a financial hit and a lost opportunity.

That $800 repair at market rates should drop into warranty expense at $800. That way you know that had that comeback repair not happened, you could have made a full $800 deploying that technician on something else.

Using Fullbay to Track Comebacks

Fullbay makes it easier to see what kind of comebacks you’re facing.

Tracking and reporting comebacks with Fullbay is a snap.

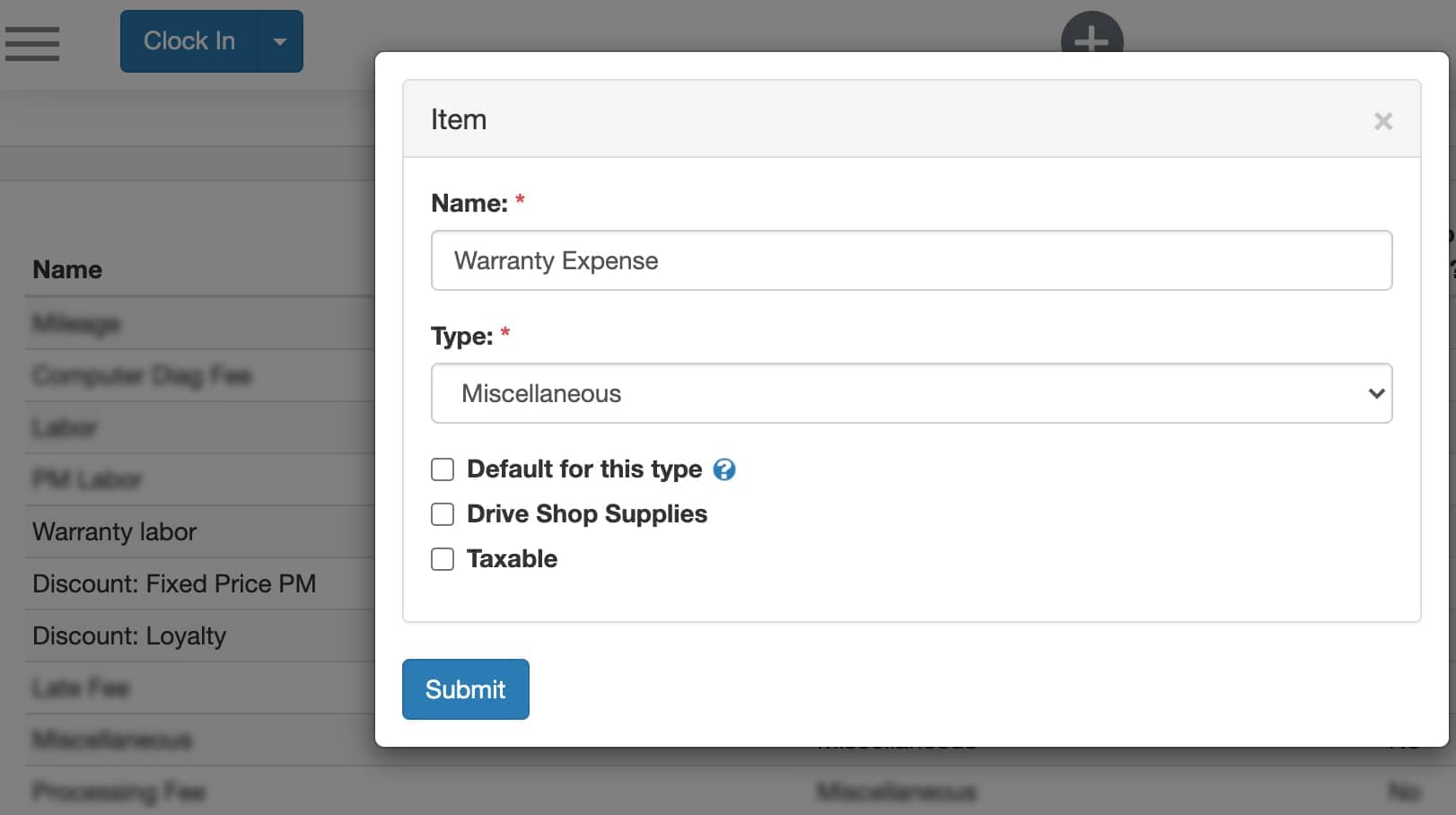

You can set up a “comeback tracker” in Fullbay by creating a new item in Configuration / Items. We suggest calling it “Warranty Expense” and we’ll refer to it as a tag. You’ll then map (or connect) the new tag to QuickBooks.

Each time you have a comeback, you can add the “Warranty Expense” tag to it original invoice. This essentially takes the place of the credit memo we discussed above.

When you want to review your comebacks, all you have to do is select this tag and you’ll see a list of invoices that have turned into comebacks. You can see what the repairs were, who made them, and start improving the rate at which they appear.

Preventing Comebacks, One Tech At A Time

Measuring your comebacks might seem like needless extra work at first, but it’s an excellent way to help your shop (and your bottom line) improve. To see how Fullbay can help you with this – and to check out what else it can do – head over to our free demo. You won’t believe how much more efficiently you can run!