Front Shop, Back Shop, HUT!

In the last few weeks, we’ve talked a lot about the way successful shops run. We examined additional data from our State of Heavy-Duty Repair report and discovered possible correlations between the use of labor guides and income, for example, as well as the connections between shop revenue, wages, and efficiency.

Today, we’re following that theme and exploring the way a particularly successful and busy shop runs.

Our victim is the always-gracious Troy of TDI, one of Fullbay’s first customers. A comment he made during our recent Shop Owner’s Roundtable about how TDI handled their workflow sparked chatter and curiosity, and we asked Troy to elaborate on their process.

He describes it as an almost graphical/blown out version of the Fullbay workflow. He’s a big fan of Fullbay and wanted to add his own spin on the process to help make sure a ticket was correct before a truck was taken in for repairs.

TDI is a big shop—it covers 10 acres. The actual work that comes into the shop is directed there through many sources, including sales, referrals, and drive-ups. Whoever brought in the vehicle would write out a service estimate, but things were still getting stopped up because that estimate might not be correct. “There are countless ways for a piece of equipment to come in but not actually be ready for a tech,” Troy explains.

- A repair estimate might be written incorrectly

- A technician might disagree with the initial approach to a repair

- A job might be marked as ready to be worked on, but isn’t (lack of parts, etc.)

Troy saw that TDI was losing efficiency. There had to be a way to get ahead. But how?

He turned to the shop’s whiteboard and an idea was born.

FRONT SHOP VS. BACK SHOP

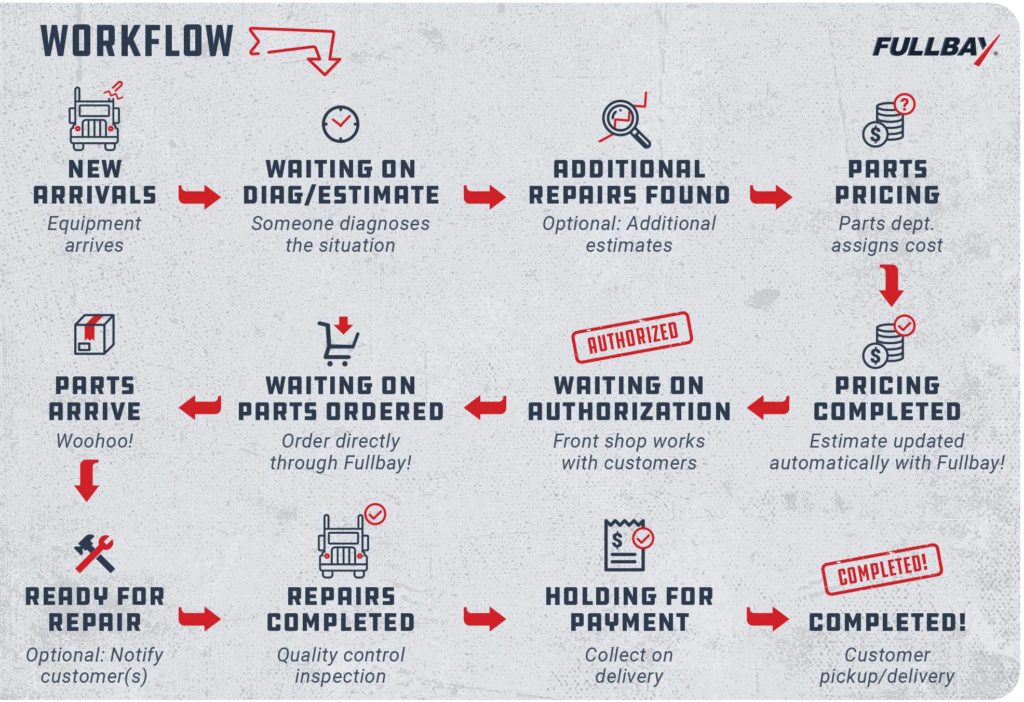

Troy took the processes that existed within Fullbay and brought them to life on the whiteboard. He then looked at where things were getting stuck and created a new workflow to nip those problems in the bud.

Essentially, he divided up the work between “front shop” and “back shop.”

These processes represent “additional states of being,” or where a repair is in the workflow. Everything from approval to “it just got here” (whether it’s from a referral, sales, or drive-up) is called front shop. Everything from customer approval or shop approval to finishing up the invoice falls under back shop.

We’ll get more into the magic that is the front shop in a moment, but overall, the workflow ensures that when a unit finally reaches a technician or repair bay, it’s ready to be worked on and the parts are in hand. There are no more hang-ups or snags with not having this or that part, or an estimate not being entirely correct. Once a unit has passed through the front shop, it’s ready.

It also gives the technicians and their supervisors a chance to just focus on the work, rather than bouncing between the bay and customer service. This was important to Troy: “Let the guys who are pounding at it every day not worry about the drive-ups and being interrupted. They’re mentoring the techs, getting things in and out, getting work completed at our expected quality levels, and that it’s billed correctly.”

So, here’s how the philosophy plays out:

FRONT SHOP IN ACTION

Service managers play a critical role in the front shop. They ensure everything is correct and all approvals are done. They’re handling all the prep work.

Fully 60-70% of the front shop diagnostics are completed by the front shop person (usually a service manager). Often, vehicles come in with a specific complaint: this one needs a brake job, this one needs an oil change.

Their duty is then to assign the job to the right person and confirm the parts on the estimate are actually physically in the shop and are indeed what the job needs. If a ticket arrives from sales, for example, the front shop guy will go outside and review the ticket and the unit once it arrives. He’ll either say “Yep, looks good” or “I don’t agree.”

By getting all of that out of the way—by building the ticket—once the job is handed to the tech, they can get started, finish up, and invoice quickly.

BACK SHOP IN ACTION

The back shop represents the actual repair and getting a unit back to the customer. This is more familiar ground for all of us, so it’s by nature a shorter section. The tech assigned to the job takes charge. The parts are available, the estimate is correct. All the tech has to do is get to work.

“On the vast majority [of tickets], that’s the first time the tech has seen the equipment, and everything has been done for him to get it to that point,” Troy says.

The front shop/back shop division of labor is also useful for promoting technicians who may not want to make the jump into the service manager role. “The back shop supervisor doesn’t have to be good at the front shop side,” Troy says. “If we’re looking at moving a technician into that position … his skill set isn’t necessarily looking at a $50K repair and writing that bid and doing that type of work. His job will be deciding which technician is best suited for that repair and recognizing that the parts that were purchased are there, and making sure we don’t bring [the unit] in until we can finish up in one fell swoop.”

A VISUAL REPRESENTATION OF FULLBAY

As mentioned, these processes all exist within Fullbay, but Troy and TDI found that combining an old-school visual representation of the workflow with Fullbay’s powerful process helped to not only keep everyone on track, but also helped the company stay on the same page as a team.

Here’s how he has set it up:

Picture, if you will, long rectangular magnets. Each one represents a repair or a customer unit. They are marked with customer, SO number, arrival date, and as it moves through the process it’ll get hours of labor needed to complete the repair and estimated start dates. Once it’s assigned, it’ll have an estimated completion date.

Certain points of the workflow trigger communication with the customer. That, Troy believes, has done the most to smooth out relationships. “We learned when you have these [built-in] points where you have to communicate, we zero out our problems. We just don’t have trouble anymore with the customer … We became better.”

THE CATEGORIES

Repairs can move through different workflow categories while the unit is in the TDI yard. Note that these units can move back and forth in categories—sometimes a unit is ready to be worked on, for example, but it bounces back to “Needs Authorization” or “Parts.”

Troy explained the workflow a unit will pass through, from start to finish:

Troy has also broken out additional categories for Needs Inspection and Assigned to a Mobile Technician, as well as Outside Service (usually pickup trucks, cars, and other vehicles they don’t work on).

Keep in mind that most of these categories are being simultaneously completed in Fullbay as well. While the whiteboard helps TDI’s flow, Fullbay is working alongside it by allowing real-time inventory tracking, efficiency monitoring, and most importantly, fast invoicing at the completion of the repair.

A DELIBERATE ACTION

Troy stressed that he uses and loves Fullbay. And it does contain all of this information. But TDI found adding a whiteboard added a little something extra and allowed them to see it all at once. The whiteboard also makes it easy for Troy to point at a chunk of board and say, “You look at this—this is your job.”

He views the actual moving of the magnet as a deliberate action. “On a spreadsheet, or on Fullbay, you can accidentally move things. With the magnet, it’s all done with a wet erase and you physically have to walk over there and intentionally add or remove data from this magnet.”

And in regards to the visual itself, Troy points out that a lot of people who own shops are mechanics, and “mechanics are very visual. So I like a very visual interface.”

Will the next iteration of Fullbay be a Star Trek-type whiteboard?

Well…probably not. We’re still working with the technology we’ve got, which means we cannot quite yet boldly go where no repair shop software has gone before.

Until then, there’s a whiteboard.